Guide Bar Manufacturers

Author:admin Date:19-09-2022

There are several advantages of using Guide bar manufacturers. One of these is that you can cut down on the procurement costs and improve your supply chain. Another advantage of using Guide bar manufacturers is that you can compare prices from different suppliers. This way, you can pick the best one. You can find the most economical and active Guide bar manufacturers. There are many Guide bar manufacturers in China. You can compare and select the best one based on their reputation and quality.

Another advantage of buying guide bars from a manufacturer is that you can customize them to fit your specific needs. Manufacturers typically offer a wide range of sizes and shapes for consumers. Typically, guide bars are a little less than a pound in weight. Depending on the length of the bar, you can get a guide bar that is just right for your machine. To get a quote, fill out the form below.

When choosing a guide bar, choose one that has oil holes to reduce the risk of cracking at the edges. These bars can be made from various materials, depending on the specifications. A standard guide bar is made of steel, but can also be made from carbon steel or other alloys. Some of these are hardened along their edges, while others are softer. Hardened edges are more resistant to wear. This is particularly important for guide bars used in conveyor systems.

Hardness of the guide bar is also an important factor. A hardened guide bar is more durable when the edges are not cracked. Hardness at the edge of the guide bar will reduce the chance of concentrated bending and wrinkling. The hardness of a guide bar will vary depending on the application. Hardness is generally defined as an area of a guide bar that is between forty-five and sixty-four Rockwell C. The remaining region should be between forty-five and fifty-two HRC.

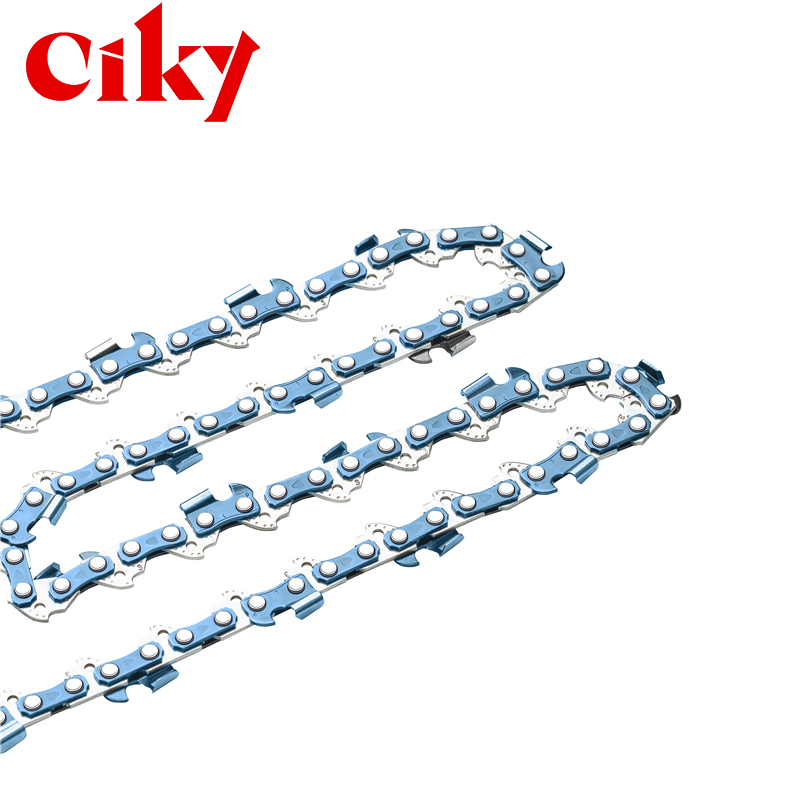

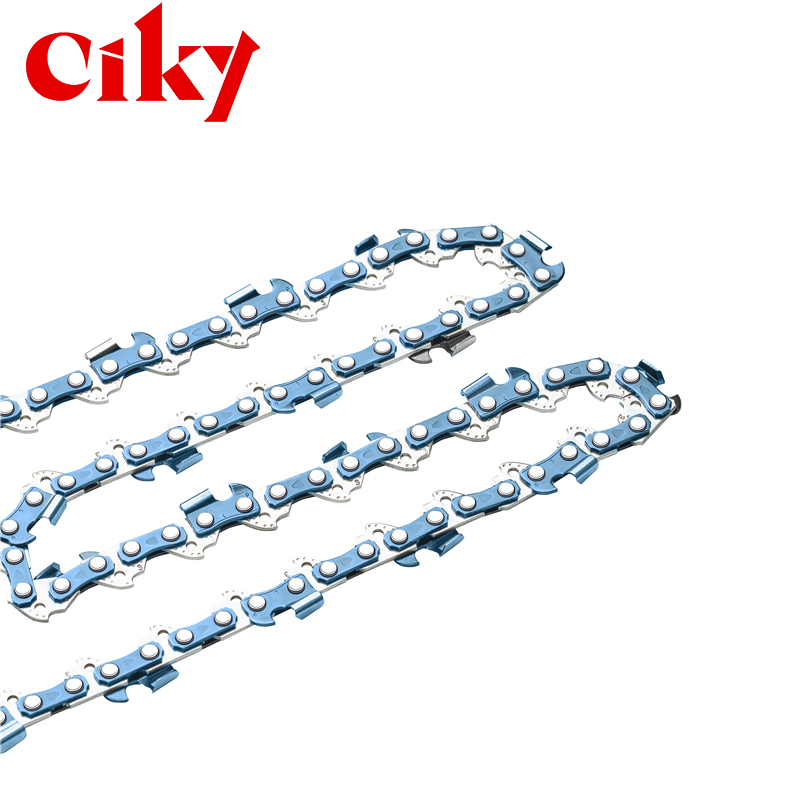

One of the main benefits of using guide bars is that they can prevent the chain from slipping. Steel chain saws are made using 3-piece guide bars that are made with solid steel. They are manufactured by feeding a giant roll of stainless steel into a stamping press. This machine then cuts the guide bar's nose and sides. The guide bar is then welded by an electro-welding machine, which uses electricity and up to 20 tons of pressure. Finally, guide bars are precisely cooled to prevent warping. Factory workers also handle changeover processes, quality control, and maintenance.

In addition to guide bars, chain saws also use a chain saw. This powerful tool can be used for clearing brush, cutting trees, and other tasks. When used correctly, a chain saw needs to be lubricated and properly guided. Its guide bar is an integral component of the chain saw and plays an important role in its operation. The hardness of the guide bar is a critical factor for the smooth operation of the chain.

English

English Español

Español